e4ships preceding project (2009-2016)

The previous lighthouse project e4ships literally aimed to test the waters by pioneering the use of fuel cells for electric power generation on board larger ships. Its aim: to reduce emissions such as sulphur dioxide, nitrogen oxide, carbon dioxide, carbon monoxide and particulate matter, thus helping to mitigate climate change and protect the environment.

The e4ships project was the first to successfully demonstrate new technical solutions for reducing ship emissions using fuel cells. Their combined heat, power and cooling configuration (CCHP)

makes the piloted systems particularly efficient. Compared to conventional systems powered by marine diesel or heavy oil, this trigeneration system was able to significantly reduce noise levels

and lower exhaust emissions. Its decentralised and modular approach not only makes for flexible and safe onboard configuration, but offers substantial advantages in the form of systems redundancy

(Safe Return to Port – SRtP).

By the same token, the specialist agencies charged with compiling national, European and international regulations, norms and standards have formulated common standards in a bid to ensure that

international shipping is able to leverage alternative fuels and fuel cells. Regular project meetings provide a platform on which project partners can share their expertise. Their joint

communications heighten the visibility of the e4ships2 project in the sector, at the political level and also amongst the public at large.

The superordinate module, Toplaterne, investigated the impacts on the climate and economic efficiency as well as on technical safety standards. Its brief encompasses the go-to-market strategy,

also for fuels that are currently still not regarded as conventional, such sulphur-free diesel or methanol.

The two sub-projects – SchIBZ and Pa-X-ell – are dedicated to the practical use of fuel cells in the maritime sector. Amongst other things, findings from these two demonstration projects have

been fed into globally valid rules and standards for the licensing and installation of fuel cells on ships.

In addition to the actual testing of fuel cells, the projects devised standards for regulating the use of low-emission fuels, such as sulphur-free diesel, natural gas or methanol on ships,

including their bunkering portside. Here again, the idea is to ensure these innovative technologies can be used worldwide in future.

Pa-X-ell

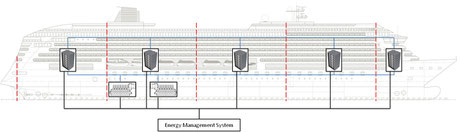

Spearheaded by the Meyer Werft shipyard, the Pa-X-ell project worked with its partners to test the use of high-temperature proton-exchange membrane (HT-PEM) fuel cells in various applications, its long-term objective being to decentralise power generation on passenger ships.

Pa-X-ell has set up two demonstration systems over time to build its experience. At its first test rig, which is based onshore, an absorption refrigeration system was installed in a 20-foot container in order to gain initial practical experience with fuel cells and to test their interaction with the cooling system. Located on Meyer Werft’s premises, this demonstration unit will continue to be used for long-term tests.

The second fuel cell demonstration system – installed on the RoPax MS Mariella which operates between Stockholm and Helsinki – involved the design and installation of a 60-kW prefabricated unit on the ferry's sun deck. A methanol tank was also put on board and filled by a land-based tanker truck.

Toplaterne

Toplaterne’s strategy module was designed to:

- Compare and assess the ecological sustainability and energy efficiency of existing ship-based energy supply systems with the hydrogen and fuel cell technologies researched in this project.

- Calculate the investment and operating costs required for fuel cell systems. Then, using this a basis, identify future potential for optimisation and possible impacts on economic efficiency.

- Define the technical strategies for systems application and expansion, taking account of the typical spatial, weight and performance requirements of seagoing vessels.

Toplaterne's brief includes assisting in the formulation of globally valid rules and standards for fuel cell licensing and installation and for the onboard use of low-emission fuels, such as sulphur-free diesel, natural gas or methanol, including their bunkering portside. Discussions and coordination with the International Maritime Organisation (IMO) are of vital importance here.

SchiBZ

The SchIBZ project was conducted by a project consortium under ThyssenKrupp Marine Systems. SchIBZ is dedicated to the development of a scalable integrated hybrid fuel cell system with a 50 to 500-kW capacity for oceangoing vessels.

This fuel cell aggregate is intended as the primary source of electric power for seafaring vessels of all kinds. It presently uses sulphur-free diesel – the same fuel used in road transport – but

plans to switch to natural gas in the medium term. An efficient hybrid system with an electrical output capacity of around 50%, it features an energy-efficient lithium-ion battery that balances

out the variations in dynamics in the fuel cell and onboard grid.

Practical testing involved a 100-kW system operated under real conditions while containerised on a ship for 12 months to power the onboard grid.

Fuel analysis

The findings of the e4ships analyses showcase the great potential of fuel cells used in combination with eco-friendly fuels. Since their efficiency outperforms conventional energy converters for ships, these technologies are set to make a key contribution to the reduction of noxious emissions in shipping, and CO2 especially. The possibilities that fuel cells offer for improving the energy-emissions balance prove that these technologies – combined with eco-friendly fuels – can considerably lower ships' GHG emissions.